Newsletter - March 2016

Sometimes the biggest benefits are found in the smaller package....

Nikon Alto CMM

The Nikon Alto CMM providing a cost effective entry level CMM that will never compromise your measurement performance.

Featuring many advanced technologies that are normally only found in larger more expensive systems, the Nikon Alto’s performance will always impress.

From first article to final inspection, fixture calibration to troubleshooting, ALTO is the perfect quality control tool for inspection and production departments alike.

Click below to view more details

Machine model

The small half-gantry design combines aluminium construction, air bearings and state-of-the-art electronics with today’s most intelligent CMM software for outstanding performance.

- Aluminium alloy beam and spindle, micro-machined for additional precision

- Zero hysteresis friction drive on all axes for smooth motion control

- High accuracy 0.1 μm optical scale system

- Also available as manual version with the option to upgrade to CNC at a later date on-site.

Model Sizes

Nikon currently offer two sizes of their Alto CMM range

| Name | Measuring Stroke | Overall Dimension | Weight | |||||

|---|---|---|---|---|---|---|---|---|

| X | Y | Z | Width | Length | Height | Max. part | Machineg | |

| Alto 5.4.4 | 500mm | 400mm | 440mm | 929mm | 888mm | 2411mm | 300Kg | 300Kg |

| Alto 6.5.4 | 600mm | 500mm | 440mm | 1044mm | 1018mm | 2411mm | 300Kg | 390Kg |

Probing

Our systems offer total probing flexibly, they can be configured to accommodate both contact and/or scanning applications

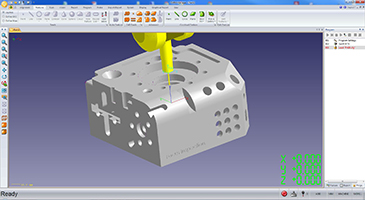

Software

Making CMM Measurement Simple...

CMM-Manager is by far the best value-for-money inspection software available.

Simply put, users accomplish more in less time with CMM-Manager. The software, being highly intuitive, assists with all tasks associated to the inspection and reporting of your components.

Fully integrated measurement environment.

- Click-and-measure capability.

- CAD-based and task-oriented graphical programming.

- DMIS part program support covering high-level language.

Advanced path planning.

- Automatic probing angle selection.

- Collision detection and smart collision avoidance.

- Inspection path optimization.

Fully integrated measurement environment.

- Click-and-measure capability.

- CAD-based and task-oriented graphical programming.

- DMIS part program support covering high-level language.

Advanced path planning.

- Automatic probing angle selection.

- Collision detection and smart collision avoidance.

- Inspection path optimization.

Powerful alignment tools.

- 3-2-1 alignment for prismatic datum features.

- CAD alignment for freeform surfaces.

- Iterative datum alignment for soft fixturing.

Convenient reporting functions.

- Drag-and-drop graphical report creation.

- Various combination of customisable text and graphical report.

- Complete GD&T support.

To book a demo please contact us by clicking here.

Key Benefits of the Nikon Alto CMM

The Nikon Alto CMM provides a wealth of benefits:

- Affordable

- Diverse & flexible probing options

- Advance interactive CMM Software

- CNC or manual options available

- Small footprint

Demonstration & Training

Focus Inspection

Foxley E, Kington Park

Malmsbury Raod

Kington st Michael

Chippenham

Wiltshire

SN15 5PZ